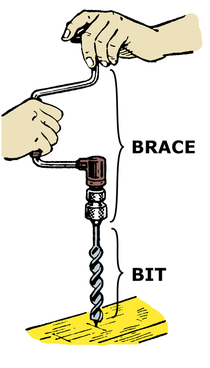

Spofford Style Bit Braces - 1897

Featured Braces - The Barber Brace, Dolan's ratchet patent

Peck, Stow & Wilcox Co..

PEXTO Braces

Another source (for information about all sorts of old hand tools) is:

Walsh, Peter C., Woodworking Tools 1600-1900, Smithsonian Institution. The e-book version is downloadable for free from Project Gutenberg. Information about augers is found starting at location 515.

RSS Feed

RSS Feed